Anticipate airflow issues and reduce PUE with thermal modeling and simulation best practices

🖋️ Par Stefano Morlacchi

CAE Application Engineer at Var Industries S.A.S.

A few years ago, a major tech player launched its brand-new data center just outside of a big city. The infrastructure was cutting-edge, the servers ultra-powerful, and the marketing promises bold: high availability, maximum security, energy efficiency. Yet, only weeks after going live, the temperature alerts started piling up. The outcome? Overheated equipment, unexpected shutdowns, costly emergency interventions. The cause? Thermal design had been overlooked.

This story isn’t unique. Today, data centers account for nearly 2% of U.S. electricity consumption, and that share is growing at 12% annually, driven by the rise of cloud computing, AI, IoT, and digital services in healthcare, finance, and public administration. A large part of that energy is consumed by... cooling systems.

And yet, thermal management is still often treated as an afterthought. At Var Industries and Siemens, we believe it’s time to reverse that logic: thermal thinking should come first, from day one. And the key to making that shift is CFD (Computational Fluid Dynamics) simulation tools.

Why simulate? Because you can’t control what you can’t see

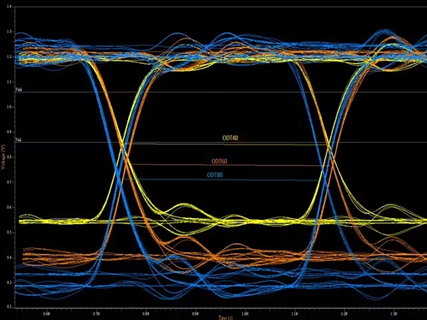

Imagine being able to see, long before a single server is installed:

- How air will circulate across every aisle, every rack

- Where recirculation zones or dead spots may form

- Whether your containment strategy will actually be effective

- How your system will handle future power increases

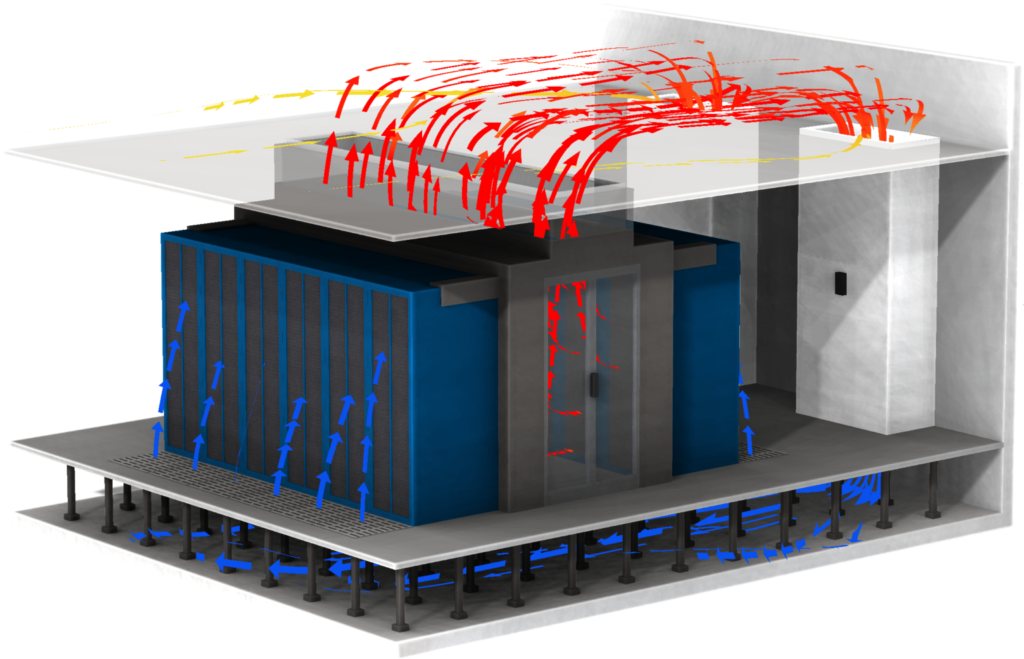

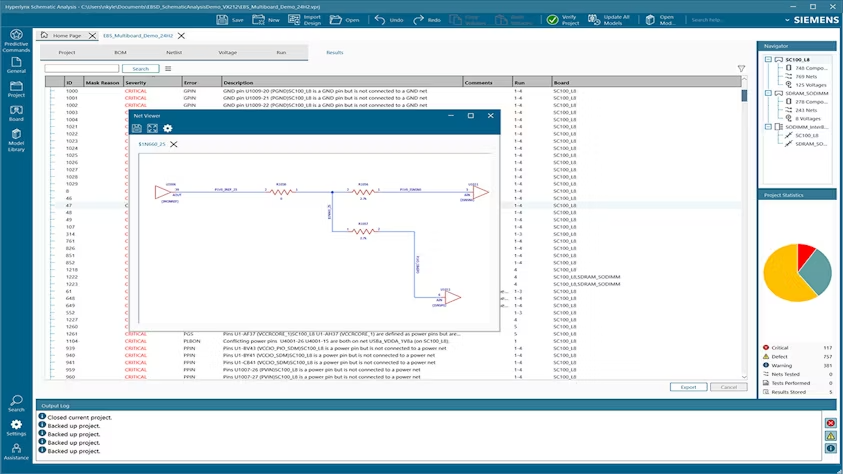

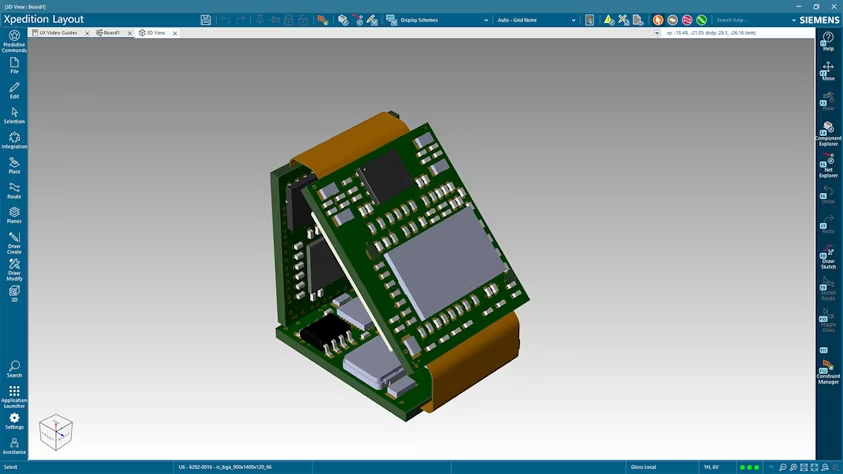

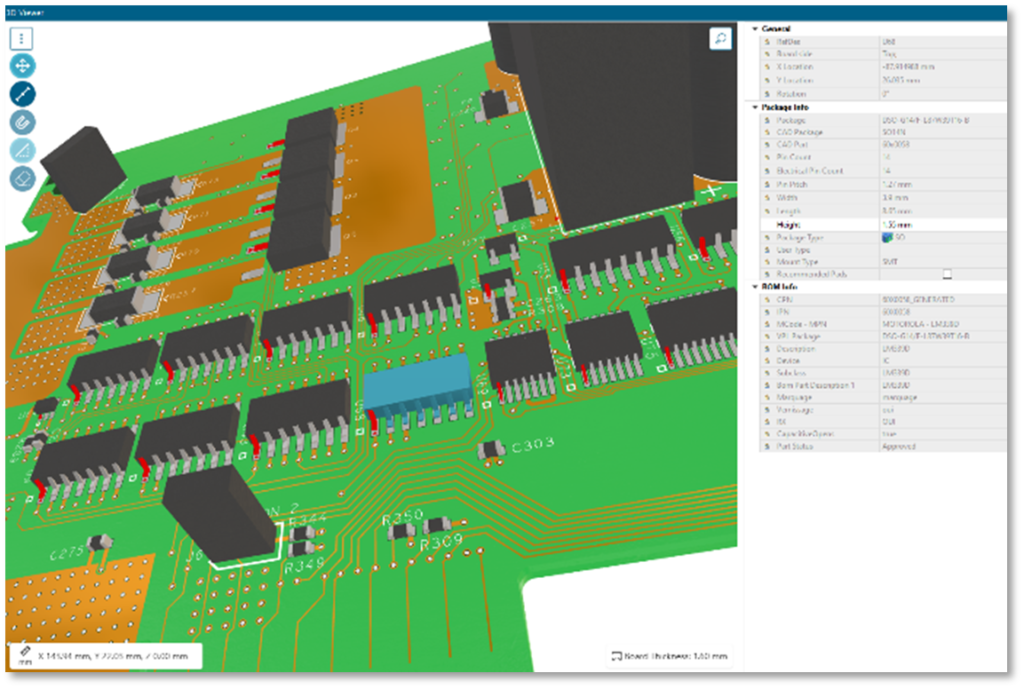

That’s exactly what a tool like Simcenter Flotherm enables. It creates a detailed thermal “digital twin” of your data center, modeling airflows, temperatures, and real-world behavior of components (racks, CRACs, floor tiles…). You can validate before you build.

9 Practical Levers for Better Thermal Design

Here are the key best practices we use with clients to ensure thermal reliability, scalability, and cost control:

- Start early — always

Thermal efficiency starts before construction. During greenfield planning, integrating HVAC layout, rack positioning, cabling, and hot-swapping logistics can prevent costly inefficiencies. Siemens sites following this model achieve PUEs of 1.15 to 1.2.

- Build a baseline model

Use Simcenter Flotherm to create a reference thermal model, including racks, cooling units, raised floor airflow, and physical obstacles. You’ll detect risks like air stratification and recirculation from the start.

- Import real design data

Thanks to the FloXML schema, you can import accurate CAD or DCIM data to ensure your model faithfully reflects the real configuration.

- Use Smartparts for real thermal behavior

Smartparts are intelligent components that simulate the actual airflow behavior of racks, CRACs, floor tiles, etc. They let you model temperature gradients through a server stack — improving simulation accuracy significantly.

- Compare cooling strategies

Should you choose cold aisle containment? Rear-door heat exchangers? Liquid cooling? CFD lets you test and compare setups such as:

- Hot/cold aisle containment

- In-line cooling

- Rear-door heat exchangers

- Rack-level liquid cooling

- Ceiling ducting and chimneys

- Free-air evaporative cooling

You can choose the most efficient strategy for your layout and load.

- Simulate site evolution

A data center is never static. Whether you’re expanding, modernizing, or densifying, each change can be simulated ahead of time to prevent new thermal risks — especially hot spots.

- Use the Capture Index (CI)

The CI measures how well cold air reaches the racks and how effectively hot air is removed:

- Cold aisle CI: % of intake air coming from cooling systems

- Hot aisle CI: % of exhaust air properly routed to return vents

A CI close to 100% = optimal cooling, minimal recirculation.

- Accelerate simulations with localized meshing

Simcenter Flotherm uses adaptive meshing to concentrate calculations on high-impact areas. That means faster simulations with no loss in detail — ideal for rapid scenario testing.

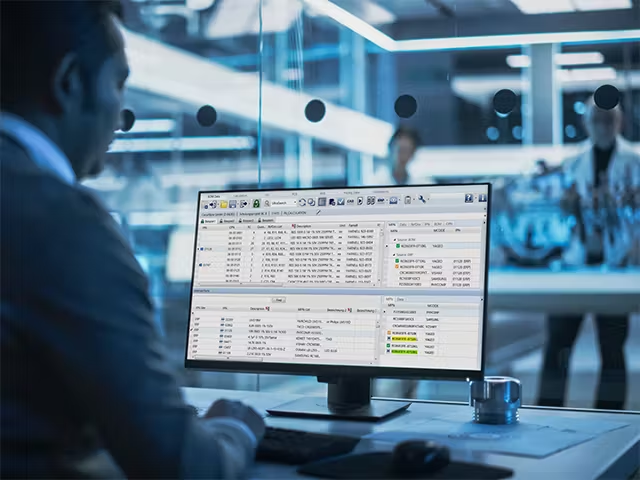

- Automate thermal optimization

With Simcenter Command Center, thermal parameters like CRAC flow rates can be automatically adjusted to find the best setup — no manual trial and error needed.

And after commissioning? Simulation continues

Once your data center is operational, changes are inevitable. New racks, new servers, even minor reconfigurations can disrupt airflow.

That’s why it’s essential to simulate before you deploy, every time. With simplified spreadsheet-based interfaces and viewers like Floviz, even non-CFD specialists (e.g., field technicians) can run or interpret thermal simulations on the fly.

Two KPIs that truly matter

🔹 PUE (Power Usage Effectiveness)

PUE=Total Site EnergyIT Equipment Energy\text{PUE} = \frac{\text{Total Site Energy}}{\text{IT Equipment Energy}}PUE=IT Equipment EnergyTotal Site Energy

A PUE ≤ 1.6 is a solid goal. Top-tier sites reach 1.2 or lower.

🔹 CI (Capture Index)

Often more insightful than heat maps, CI helps diagnose airflow inefficiencies that might otherwise go unnoticed.

Final Thought: Simulate to Stay Reliable

The lesson?

A high-performance data center isn’t just about kilowatts or uptime. It’s about resilience, scalability, and long-term efficiency.

And that starts with a comprehensive approach to thermal design, built on simulation.

👉 Anticipate risks

👉 Optimize airflow

👉 Adapt to changing loads

...and you’ll build a data center that’s future-ready, stable, and cost-effective.

Vous êtes confronté(e) à ces enjeux ? Contactez-nous pour découvrir comment nous pouvons vous accompagner concrètement.

Notre expert commercial :

Frédéric Benamor – Chief Sales Officer

📧 f.benamor@cadlog.com | ☎️ +33 6 30 94 63 15

ARTICLES SIMILAIRES :

Vous voulez rester à jour sur le monde de l'électronique?

Inscrivez-vous à la newsletter de Cadlog!